|

DMX Connectors

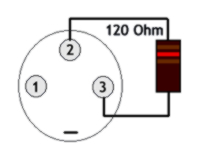

DMX lines are made up of either 3- or 5-core shielded data cable terminated at either end with 3- or 5-way XLR type connectors (one male, one female). The DMX data itself requires only 3 of the cable cores, so more modern devices have started to use the 3-core alternative. In 5-core Cables, the two spare cores have no defined purpose The wiring of the XLR connectors is shown below:

Where DMX is involved in a rig, routing must be carefully planned out. As always, the cabling should be as discrete as possible, so running it along truss is desirable wherever and whenever possible. In order for the DMX to be transmitted to every piece of equipment that needs to receive it, a through-route needs to be determined for the DMX line starting at the console and ending with the furthest device from the console. Each device must be connected in a daisy-chain fashion.

DMX Terminators

The last device on the DMX line must terminate the line to avoid serious signal beak down due to signal reflections and external electro-magnetic interference. Some modern devices have a switch on them to tell them that they are the last device on the line and that they should terminate rather than expect something to be plugged into their DMX out port. Other devices can sense an empty out port automatically and act according to terminate the line. There are some pieces of equipment which do not automatically terminate and do not feature built in termination and in these cases, termination must be supplied. The best way of doing this is connecting a resistor between 100 and 120 ohms in size across Data + and Data - as shown in the diagram above left. The last device on the DMX line must terminate the line to avoid serious signal beak down due to signal reflections and external electro-magnetic interference. Some modern devices have a switch on them to tell them that they are the last device on the line and that they should terminate rather than expect something to be plugged into their DMX out port. Other devices can sense an empty out port automatically and act according to terminate the line. There are some pieces of equipment which do not automatically terminate and do not feature built in termination and in these cases, termination must be supplied. The best way of doing this is connecting a resistor between 100 and 120 ohms in size across Data + and Data - as shown in the diagram above left.

Power Connections

The most common connectors used are ceeform type, an industry standard for all circuits over 15A. There are three main classes of ceeform connector:

110V 1-phase CEE

Used in some countries, 110V supplies arenít very widespread but are occasionally used for outdoor work and working lights.

240V 1-phase CEE 240V 1-phase CEE

This connector is available in 16A, 32A, 63A and 125A, each connector increasing in size along with its power rating. These connections are usually used to symbolise non-dimmed supplies, for example when connecting intelligent fixtures. However lately the TV and Event industry are starting to adopt 16amp CEE over the more traditional 15amp connections for dimmed supplies as well as non-dimmed supplies.

240V 3-phase CEE

Very similar to the 1-phase variety, the 3-phase connector is also available in 16A, 32A, 63A and 125A types.

There are a few other, notable connectors:

5A

Although small and once very common, the 5A connector has almost been completely phased out although its still around in a large number of schools.

IEC

Otherwise known as a kettle lead, this is a simple 3-pin connector found on low-power rack units. It can handle up to 6A.

13A 13A

You know it, youíve used it, itís the 13A connector. The main disadvantages in theatre usage of the 13A connector is the fact that is contains a fuse (which is difficult to find and replace) and that you canít tell if the circuit that it is on comes from a normal ring main or a dimming circuit.

5A 5A

The most common lighting connector, the 15A has no fuse and is fairly cheap and sturdy. If your cable has a 15A socket on the end, you can usually assume that the circuit has a dimmer on the other end. By not having an inbuilt fuse, it means that all the circuit protection can be centralised at your power supply, reducing the time spent finding and fixing faults.

Socapex

Carrying 6 channels of 10A power using a circular connector.

|